What is Thin Joint Technology in Block Construction? The Future of Masonry is Here

The construction industry is often viewed as traditional and slow to change. For centuries, the image of a mason slathering a thick layer of wet cement between rough bricks has been the standard.

But in the last decade, a silent revolution has taken place. With the advent of precision-engineered masonry units like AAC (Autoclaved Aerated Concrete) Blocks, the old methods have become obsolete.

If you are a developer, architect, or homeowner building a modern structure, you cannot afford to ignore the new standard. You have likely heard the term thrown around in engineering meetings, but what is thin joint technology in block construction exactly? Is it just using less cement? Or is it a fundamental shift in how we build?

At Gritolo Global India Pvt Ltd, we are at the forefront of this shift. We don’t just sell products; we sell efficiency.

In this deep-dive guide, we will explore the mechanics of Thin Joint Technology, its massive benefits over traditional mortar, and why Gritolo’s specialized Block Jointing Mortar is the fuel driving this engine of change.

1. Defining the Concept: What is Thin Joint Technology?

To answer “what is thin joint technology in block construction”, we must first look at the geometry of the wall.

The Traditional Way (Thick Bed):

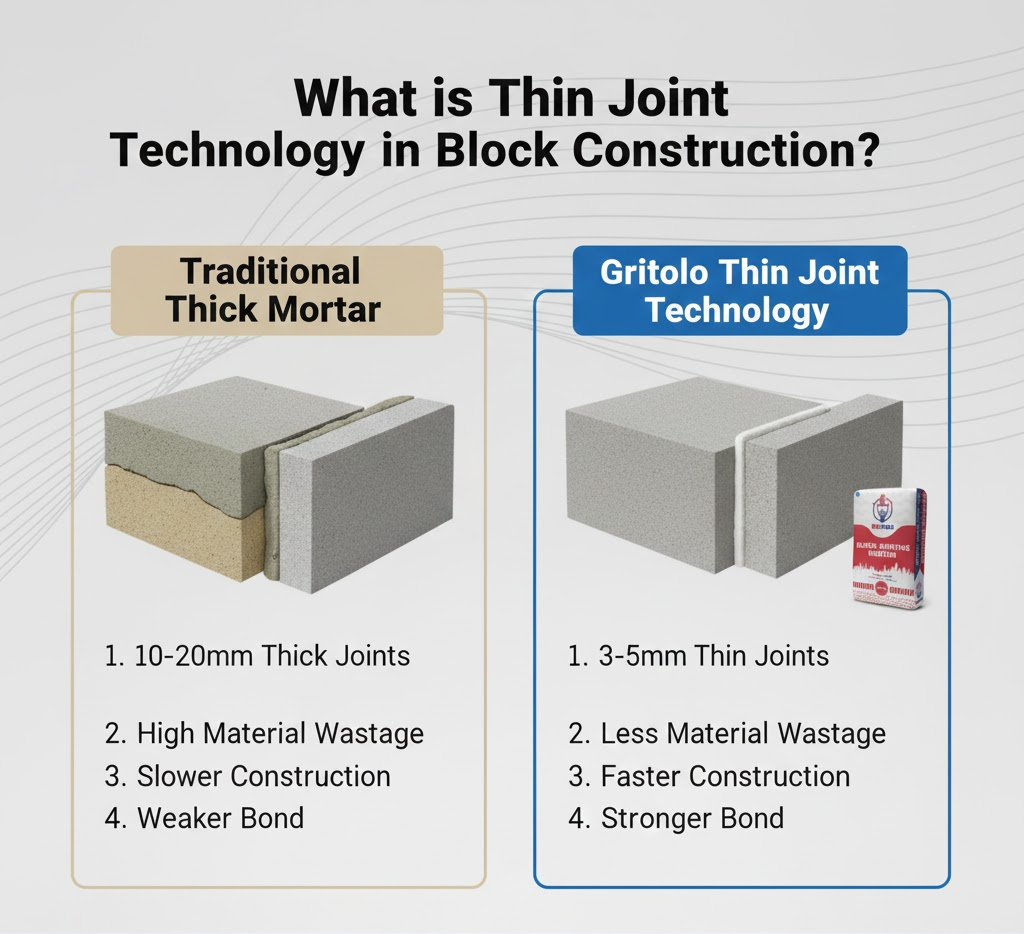

In traditional masonry using Red Clay Bricks, the bricks vary in size and shape. They are uneven. To build a straight wall with crooked bricks, the mason uses a thick layer of sand-cement mortar—usually 10mm to 15mm thick. This thick layer acts as a “leveling bed” to compensate for the irregularities of the brick.

The Modern Way (Thin Joint):

Modern AAC blocks and Fly Ash bricks are machine-cut. Their dimensional tolerance is extremely precise (often within +/- 1mm). Because the blocks are perfectly flat and true, you do not need a thick layer of mortar to level them.

Thin Joint Technology is the method of bonding these precision blocks using a specialized, polymer-modified adhesive layer that is only 2mm to 3mm thick.

It is not just about reducing thickness; it is about changing the chemistry. You cannot use standard sand-cement for thin joints (it would dry out instantly and crumble). You must use a specialized Thin Bed Mortar (like Gritolo Block Jointing Mortar) designed to retain water and bond chemically at such a thin gauge.

In summary: It is the transition from “bedding” blocks in 15mm of cement to “gluing” blocks with 3mm of engineered adhesive.

2. The Science: How Does a 3mm Joint Hold a Wall?

Skeptics often ask: How can a 3mm layer be as strong as a 15mm layer?

The answer lies in Adhesion Physics.

Mechanical vs. Chemical Bonding:

- Thick Bed (Sand-Cement): Relies on Mechanical Interlocking. The mortar flows into the rough pores of the brick. It creates friction. It is effectively a “filler.”

- Thin Bed (Gritolo Mortar): Relies on Chemical Bonding. Gritolo’s mortar contains high-grade polymers. These polymers create a molecular bond with the surface of the AAC block.

Because the joint is so thin, the tensile forces are distributed evenly. In fact, laboratory tests consistently show that the bond created by Thin Joint Technology is often stronger than the block itself. If you try to break the wall, the block will break before the joint does.

3. The Problem with Thick Joints (Why We Needed a Change)

To understand the value of the solution, we must understand the failure of the old method. Using thick mortar on AAC blocks creates three major problems:

- Thermal Bridging: AAC blocks are excellent insulators. Cement mortar is a terrible insulator (it conducts heat). If you have 15mm thick mortar joints all over your wall, heat bypasses the blocks and travels through the mortar into your building. It’s like wearing a warm jacket with holes in it.

- Shrinkage Cracks: Cement shrinks as it dries. A 15mm layer shrinks significantly, causing tension and cracks. A 3mm layer has negligible shrinkage.

- Water Wastage: Thick mortar requires gallons of water for mixing and 7 days of water curing. Thin mortar is self-curing.

4. Top 7 Benefits of Thin Joint Technology

When you ask what is thin joint technology in block construction, the answer is really a list of benefits that save time and money.

Incredible Speed of Construction

Time is the most expensive commodity in construction.

- No Curing: Unlike traditional mortar, Gritolo Block Jointing Mortar is self-curing. You don’t need to wait 7 days to plaster. You can start plastering the next day.

- Faster Laying: Using a notched trowel (a specialized tool for thin joints), a mason can spread adhesive for 2-3 blocks in one swipe. It is physically lighter work than shoveling heavy sand-cement.

- Result: Masonry work is completed 30% to 40% faster.

Improved Thermal Insulation (Energy Saving)

This is crucial for Green Buildings.

By reducing the joint thickness from 10mm to 3mm, you reduce the area of the “Thermal Bridge” by over 70%.

This maintains the thermal integrity of the AAC wall.

- Result: The building stays cooler in summer and warmer in winter, reducing AC bills for the occupants.

Material Savings & Logistics

- Volume: One bag of Gritolo Block Jointing Mortar (40kg) replaces roughly 3 to 4 bags of cement plus a large volume of sand required for the same wall area using traditional methods.

- Storage: You don’t need mountains of sand blocking your site. You just need a neat stack of bags.

- Transport: Less material to hoist to upper floors means less strain on cranes/labor.

Structural Integrity

Thin Joint walls act as a monolith. The high tensile adhesion strength improves the wall’s resistance to lateral forces (like wind or minor seismic activity). The flexibility of the polymers also allows the wall to absorb minor movements without cracking.

Cleaner Construction Sites

We have all seen the mess of traditional sites—sand mixed with mud, waste mortar dropped everywhere. Thin Joint Technology is clean. You mix a bucket, you use a scoop. There is minimal spillage. This is vital for finishing work in high-end projects.

Accuracy and Finish

Because the layer is so thin, the mason is forced to align the blocks perfectly. You cannot “adjust” a crooked block with a thick glob of mortar.

- Result: The wall is plumb and straight. This means you need less plaster later to make the wall look good.

Eco-Friendliness

- Sand Conservation: River sand is a scarce resource. Thin Joint Technology uses graded sand or manufactured sand in very small quantities, protecting riverbeds.

- Water Conservation: By eliminating curing, millions of liters of water are saved on large projects.

5. The Application Process: How It Is Done

Understanding what is thin joint technology in block construction also requires knowing how it is applied. It requires a shift in tools and mindset.

The Essential Tool: The Notched Trowel

You cannot use a regular flat trowel. You must use a specialized scoop or trowel with “teeth” (notches).

- The notches ensure that exactly 3mm of adhesive is left on the block.

- It ensures 100% coverage of the block surface.

Step-by-Step Procedure:

- Preparation: Clean the top surface of the AAC blocks. Dust is the enemy of adhesion.

- Mixing: Mix Gritolo powder with water (approx. 25-30%) using a mechanical stirrer until it looks like creamy toothpaste.

- Application: Scoop the mortar. Drag the notched trowel along the block length. This leaves “ribs” of mortar.

- Placement: Place the next block on top.

- Tap: Gently tap with a rubber mallet. The ribs collapse, spreading the adhesive to the edges.

- Check: A small amount of adhesive should squeeze out—this confirms a full bond.

6. Cost Analysis: Is It Expensive?

This is the biggest myth surrounding the technology.

“Gritolo bag is ₹XXX, but cement bag is cheaper. Isn’t this expensive?”

When analyzing what is thin joint technology in block construction, you must look at Total Applied Cost, not Material Cost.

Let’s compare costs for 100 sq. ft. of wall:

Traditional Thick Bed:

- Cement cost: Low

- Cost of Sand: High (and rising)

- Labor for sieving sand: High

- Want a labor for mixing: High

- Need labor for Curing (7 days): High

- Wastage (Rebound loss): 20%

- Total Cost: High + Slow Time.

Thin Joint Technology:

- Cost of Gritolo Mortar: Moderate

- Sand: Zero (Included in bag)

- Provide a labor for sieving: Zero

- Deliver a Labor for Curing: Zero

- Wastage: Negligible (<2%)

- Total Cost: 10-15% Cheaper than traditional, plus the project finishes weeks earlier.

Conclusion: Thin Joint Technology puts money back in the builder’s pocket.

7. Gritolo: Pioneering Thin Joint Solutions in India

At Gritolo Global India Pvt Ltd, we realized early on that India’s construction future lies in AAC blocks. But AAC blocks were failing because of bad mortar.

That is why we developed our specialized Block Jointing Mortar.

Why Gritolo is the Best Choice for Thin Joint Technology:

- Engineered Formula: Our mix design balances Open Time (so the mason doesn’t have to rush) with Setting Time (so the wall becomes strong fast).

- Polymer Power: We use high-grade European polymers to ensure flexibility and extreme bonding strength.

- Consistency: Every bag is identical. No more “bad batches” of site-mix mortar.

- Sustainability: Our product is designed to meet Green Building norms.

When you ask, “What is thin joint technology in block construction?”, the practical answer is: Using Gritolo to build better.

The Future Outlook

The Indian government and regulatory bodies (like IGBC) are pushing for sustainable, energy-efficient construction.

- Energy Codes: New commercial buildings must meet energy efficiency standards. Thin Joint Technology helps achieve the required U-values (insulation).

- Labor Shortage: Skilled labor is becoming expensive. Technologies that require less labor and less skill (like thin joint) are the future.

The question is no longer “what is thin joint technology in block construction”, but rather “why aren’t you using it yet?”

Embrace the Thin, Build the Strong

The construction industry is evolving from “More is Better” to “Precise is Better.”

Thin Joint Technology is not just a method; it is a mindset of efficiency. It respects resources, values time, and prioritizes thermal comfort. It transforms a wall from a collection of blocks and mud into a unified, high-performance barrier.

If you are still using thick mortar on AAC blocks, you are driving a Ferrari with the handbrake on. Release the potential of your materials.

Switch to Gritolo Block Jointing Mortar. Experience the speed, the strength, and the savings of Thin Joint Technology.

Ready to modernize your masonry?

👉 Call Gritolo Experts Today: +91 7397985754

👉 Request a Free Sample & Cost Comparison

👉 Visit Our Product Page

Gritolo: Building the future with precision, innovation, and grit.