How to Choose the Right Tile Adhesive Grade: The Definitive Guide to IS 15477 (T1, T2, T3)

Choosing the correct tile adhesive is arguably the single most critical decision in any tiling project. Using the wrong product—whether it’s a standard cement mortar for vitrified tiles or a low-grade adhesive for an exterior facade—will inevitably lead to tile debonding, expensive failures, and project delays.

For professionals in India, navigating the numerous options requires a deep understanding of the industry benchmarks set by the Indian Standard IS 15477. This standard classifies adhesives based on their composition and performance, providing clarity on which product is fit for purpose.

This definitive guide, brought to you by the technical experts at Gritolo Global, breaks down the entire grading system. By the end, you’ll be able to confidently select the precise Gritolo adhesive needed for any substrate, tile type, or environmental condition, ensuring long-lasting, flawless results.

1. 🧱 Understanding the Basics: What is Tile Adhesive?

Tile adhesive is a specialized polymer-modified mortar used to fix tiles to surfaces. Unlike traditional cement-sand mortar, which relies heavily on water evaporation for curing and provides only a mechanical bond, modern tile adhesives offer superior chemical and mechanical bonding characteristics.

Why Traditional Mortar Fails

Traditional cement mortar has two major flaws, especially for modern construction:

- High Water Requirement: The mortar needs significant water to cure, which is then absorbed by porous tiles and the substrate, often leading to shrinkage, cracking, and weak bonds.

- Lack of Flexibility: It lacks the polymers needed to absorb thermal and structural movements, causing debonding, especially with low-porosity tiles like vitrified and porcelain.

The Role of Polymer Modification

High-grade tile adhesives incorporate polymers (like vinyl acetate ethylene, or VAE) that provide flexibility, water resistance, and enhanced adhesion. This polymer modification is what allows adhesives to be graded higher and handle challenging applications.

2. 🔠 Demystifying the IS 15477 Classification System

The Indian Standard IS 15477: 2017 sets the performance requirements for all tile adhesives used in India. Understanding the letters and numbers in the classification is the first step toward true expertise.

The full classification code for a product like a high-performance, rapid-setting, flexible adhesive might look like this: C2TES1.

The Base Material

All adhesives under this standard are categorized by the primary binder:

- Cementitious Adhesives: Powder-based adhesives that require mixing with water (the most common type used in construction).

- Dispersion Adhesives: Ready-to-use, paste-form adhesives that are solvent-free and dry via water evaporation.

- Reaction Resin Adhesives: Two-part adhesives (like epoxy) that cure via a chemical reaction, offering very high strength and chemical resistance.

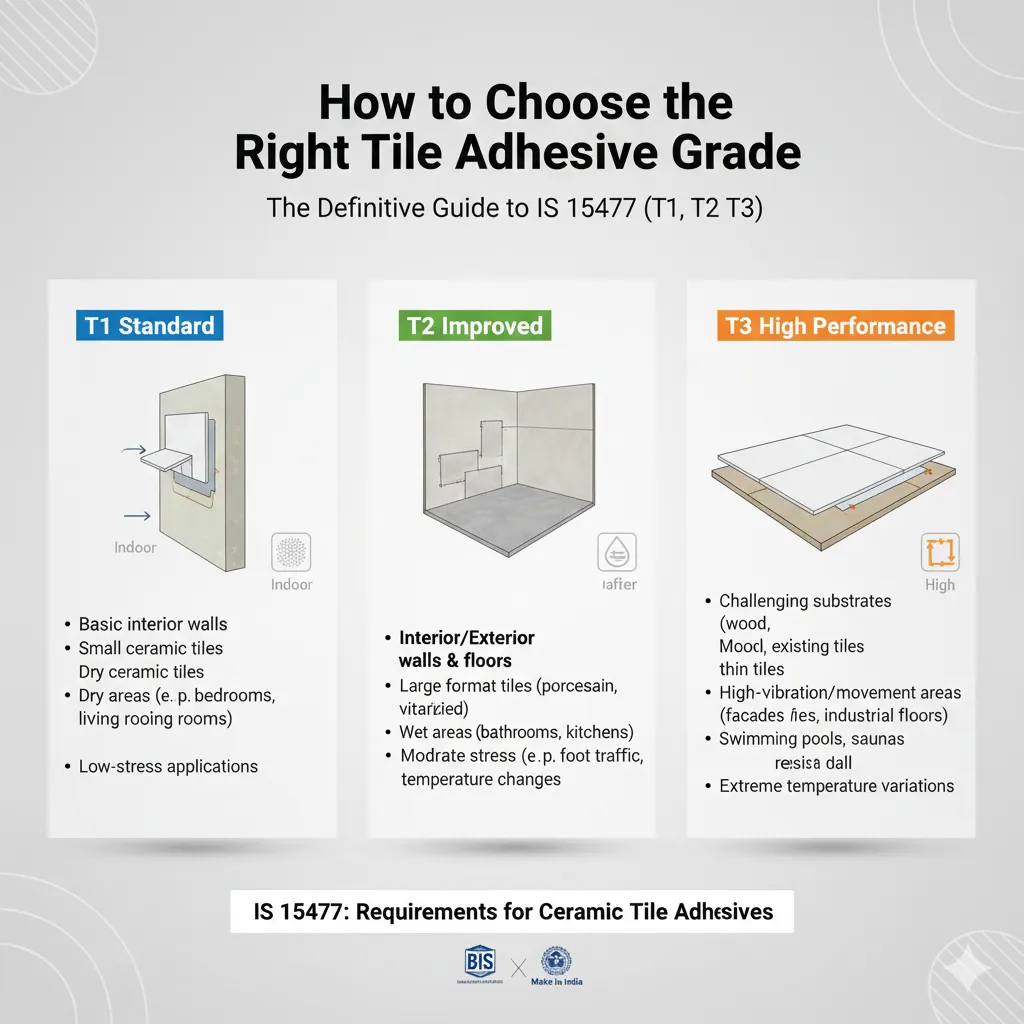

The Performance Grades T1 vs T2vs T3

This is the most crucial part of your decision, separating standard products from specialized ones.

| Grade | Adhesion Level | Typical Composition & Features | Ideal Application Scenarios |

|---|---|---|---|

| T1 (Standard) | Standard Adhesion | Basic cementitious, often with low polymer content. | Interior walls/floors, porous tiles (ceramic), dry areas, non-critical applications. |

| T2 (Improved) | Improved Adhesion | Contains higher levels of polymers. Required for vitrified tiles. | Exterior and interior applications, vitrified and porcelain tiles, bathrooms, balconies. |

| T3 (High Performance) | Highest Adhesion | Highly polymer-modified, excellent bonding strength. | Industrial floors, swimming pools, facade tiling, metal substrates, areas exposed to chemical attack. |

The Optional Symbols

These letters indicate crucial performance characteristics that are often necessary for challenging projects:

| Symbol | Definition | Feature Explained | When You Need It |

|---|---|---|---|

| T | Thixotropic / Reduced Slip | Prevents tiles (especially large, heavy ones) from sliding down a vertical wall after placement. | All vertical wall tiling. |

| E | Extended Open Time | The adhesive retains its sticky quality longer after being spread, giving the tiler more time to lay tiles before a skin forms. | Hot climates or large-scale projects where application speed may vary. |

| F | Fast Setting | The adhesive achieves early strength rapidly, allowing for quicker foot traffic or grouting | Projects with tight deadlines or quick repair work. |

3. 🎯 Grade Deep Dive: T1, T2, T3 Explained

Understanding the why behind each grade helps you avoid liability and future failure.

The T1 Grade: The Basic Standard

T1 is your starting point. It offers sufficient adhesion for porous, traditional tiles that have a water absorption rate above 3%.

- Bond Strength: Meets the minimum shear adhesion requirements set by the standard.

- The Risk: Using a T1 grade on a non-porous tile (like porcelain, which has absorption near 0.1%) means the adhesive cannot penetrate the tile body, resulting in a weak, superficial bond that will inevitably fail.

- Gritolo Solution: [Insert a hypothetical name for a T1 product, e.g., Gritolo TileFix Standard] – Use only for interior ceramic tiles on standard cement plaster.

The T2 Grade: The Industry Workhorse

T2 is generally considered the minimum grade for modern construction due to the prevalence of vitrified and porcelain tiles. The improved polymer content provides the required chemical bond for these non-porous materials.

- Bond Strength: Significantly higher shear adhesion than T1, especially after water immersion (a key test for exterior use).

- The Necessity: If the tile is vitrified, porcelain, or made of natural stone, T2 is a must. If the area is exposed to weather (rain, sunlight), T2 provides the necessary water resistance.

- Gritolo Solution: [Insert a hypothetical name for a T2 product, e.g., Gritolo TileFix Plus] – Your standard choice for all residential and commercial vitrified tiling projects, indoor or outdoor.

The T3 Grade: High-Performance & Facade Specialist

The T3 grade represents the pinnacle of adhesion and specialized performance. It is reserved for the most technically demanding applications where movement, extreme loads, or chemical resistance is a factor.

- Bond Strength: Exceptional adhesion values that greatly exceed the standard requirements.

- Ideal for: Large format tiles (LHT), high-traffic areas (malls, airports), facade cladding (where gravity and wind load are critical), and submerged areas (swimming pools).

- Gritolo Solution: [Insert a hypothetical name for a T3 product, e.g., Gritolo TileFix Extreme] – Recommended for all exterior facades and heavy-duty industrial applications.

4. 📐 The Ultimate Factor: Deformability (S1and S2)

For projects subject to significant thermal changes, vibrations, or structural movement, you need more than just high adhesion—you need flexibility, known in the standard as Deformability (S). This is often where contractors fail, leading to cracks in even T3-adhered tiling.

- S1 (Flexible Adhesives): Meets the requirement for flexibility. Essential for tiling over substrates prone to slight movement, such as wooden floors, drywall, or substrates that see high temperature changes (sun-facing balconies).

- S2 (Highly Flexible Adhesives): Meets the requirement for extreme flexibility. Necessary for high-vibration areas (e.g., industrial plants), substrates that move significantly (like metal or glass), or large-format tiles (LHT) on external facades.

When to Demand an S1 or S2 Product

| Condition | Adhesion Grade Requirement | Deformability Requirement |

|---|---|---|

| Tiling on Plywood/Wooden floor | T2 or T3 | S1 or S2 (due to movement) |

| Large Format Tiles (LHT) >1200 mm | T2 or T3 | S1 or S2 (to handle material stress) |

| Facade (External Walls exposed to direct sun) | T3 | S1 or S2 (for extreme thermal expansion) |

| Industrial or Airport Floors | T3 | S2 (due to heavy dynamic loads) |

5. 🛠️ The Comprehensive Decision Matrix (Putting It All Together)

To ensure a successful project, you must assess three key variables before selecting a product:

- The Tile Type

- Porous (Ceramic): T1 is acceptable (but T2 is safer).

- Non-Porous (Vitrified, Porcelain, Natural Stone): T2 minimum, T3 for large formats.

- The Substrate

- Standard Cement Plaster/Screed: T1 or T2

- Non-Absorbent (Existing Tile, Marble, Metal): Requires a highly specialized T3 adhesive, often with an S1 / S2 rating and a primer.

- The Environment

- Interior, Dry Area, No Traffic: T1 (T is needed for walls)

- Exterior / Wet Areas (Balcony, Bathroom): T2 minimum, with T / E and potentially S1.

- Submerged (Swimming Pool): T3 and often S2 (due to constant pressure and movement).

Your Commitment to Excellence

The choice of tile adhesive is a long-term investment in your project’s integrity. By following the precise performance standards set by IS 15477 and understanding the necessity of T2 for modern tiles and S1\S2 for dynamic applications, you move beyond guesswork and achieve professional-grade results.

At Gritolo Global India, we manufacture a comprehensive range of construction chemicals, from T1 standards to highly specialized C3TE S2 facade solutions. Every product is rigorously tested to meet and exceed the Indian Standards, ensuring your work stands the test of time.

Ready to Secure Your Project?

View the Full Gritolo Adhesive Range: Browse our catalog of certified tile adhesives, each clearly marked with its IS 15477 grade (T1 to T3 and S1/S2) to help you select the exact product you need today.

Need Technical Specification Support? For large-scale projects, facade applications, or industrial flooring, contact the Gritolo technical team for a personalized product recommendation and bulk pricing quote. We ensure you get the perfect grade for guaranteed project success.